babban tsari na samarwa ga jikin gwangwanin abinci guda uku

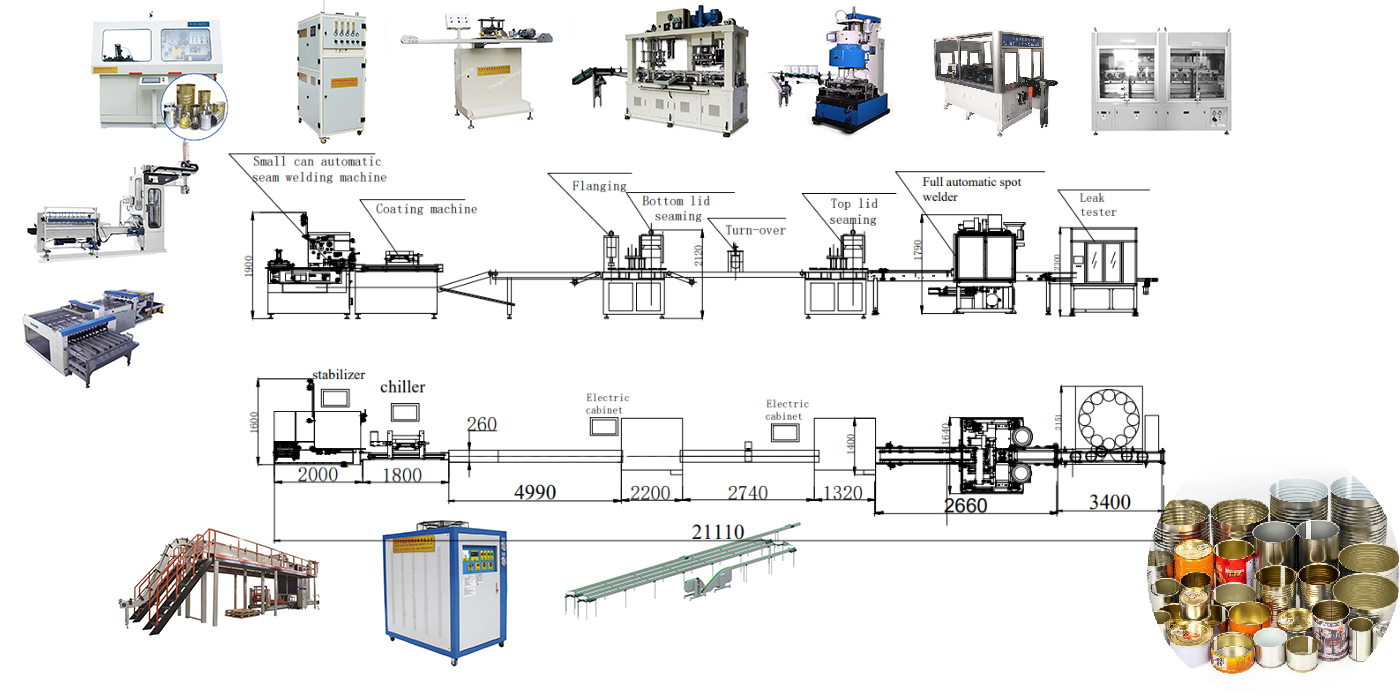

Babban tsarin samar da jiki na abinci guda uku zai iya haɗawayankan, waldi, shafikumabushewana weld dinkin, wuya, flanging, beading, sealing, leak test, full spraying and drying, and packing. A kasar Sin, da atomatik iya samar line ne yawanci hada da jiki taron inji, bi-directional sausaya inji, waldi inji, weld kabu kariya da shafi / curing tsarin, ciki spraying / curing tsarin (na zaɓi), online yayyo gano inji, fanko iya stacking inji, strapping inji, da kuma fim nadi / zafi shrinking inji. A halin yanzu, na'ura mai haɗawa na jiki na iya kammala matakai kamar su slitting, wuya, faɗaɗa, iya flaring, flanging, beading, seaming na farko da na biyu, a gudun har zuwa gwangwani 1200 a minti daya. A cikin labarin da ya gabata, mun bayyana tsarin tsaga; yanzu, bari mu bincika tsarin wuyansa:

Necking

Wata hanya mai mahimmanci don rage yawan amfani da kayan shine ta hanyar ƙulla tinplate. Masu sana'a na tinplate sun yi aiki mai mahimmanci a wannan batun, amma kawai ƙaddamar da tinplate don rage farashin zai iya iyakancewa ta hanyar matsa lamba-juriya na tsarin iyawa, kuma yiwuwarsa yanzu kadan ne. Duk da haka, tare da ci gaba a cikin wuya, flanging, da fasaha na iya fadadawa, an sami sababbin ci gaba a rage yawan amfani da kayan aiki, musamman a cikin jikin gwangwani da murfi.

Tushen farko na samar da gwangwani masu wuya ya fara motsawa ta hanyar sha'awar haɓaka samfuri ta masana'antun. Daga baya, an gano cewa wuyan gwangwani hanya ce mai inganci don adana kayan. Necking yana rage diamita na murfi, don haka rage girman blanking. A lokaci guda, yayin da ƙarfin murfin ya karu tare da raguwar diamita, ƙananan kayan aiki zasu iya cimma wannan aikin. Bugu da ƙari, ƙarancin ƙarfi a kan murfi yana ba da damar ƙaramin yanki na hatimi, yana ƙara rage girman mara kyau. Duk da haka, ɓacin rai na kayan jiki na iya haifar da al'amurra saboda canje-canje a cikin damuwa na kayan aiki, kamar rage juriya tare da axis da kuma sashin giciye na jiki. Wannan yana ƙara haɗari yayin tafiyar matakai na cika matsa lamba da sufuri ta masu cikawa da dillalai. Don haka, yayin da wuya baya rage kayan gwangwani sosai, galibi yana adana abu akan murfi.

Ganin tasirin waɗannan abubuwan da buƙatun kasuwa, masana'antun da yawa sun haɓaka da haɓaka fasahar wuyan hannu, suna kafa matsayi na musamman a cikin matakai daban-daban na masana'anta.

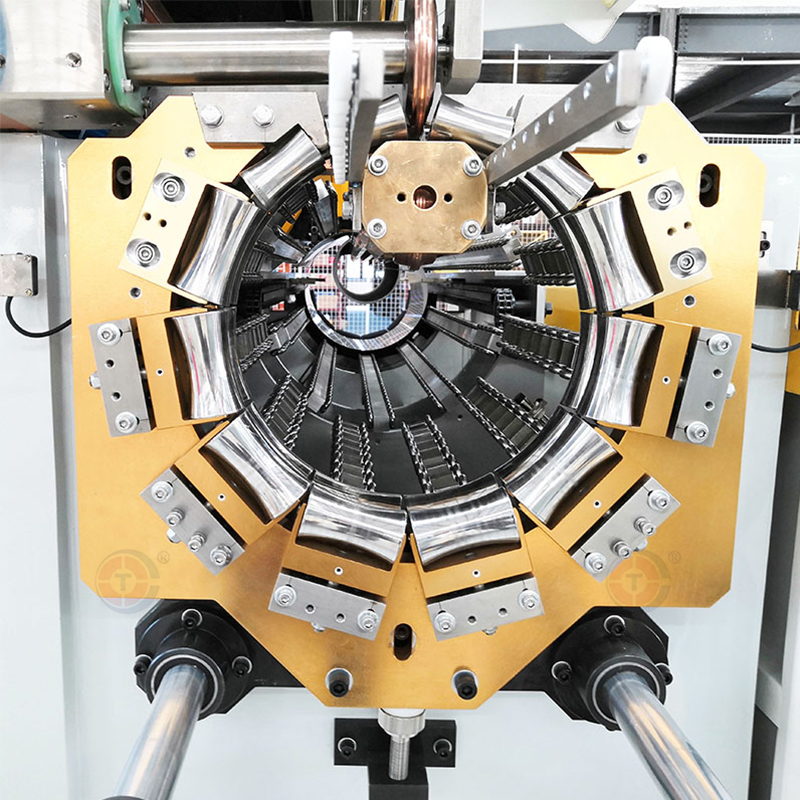

Idan babu tsari na tsagawa, wuyansa shine tsari na farko. Bayan shafewa da warkewa, ana isar da jikin gwangwani bi da bi zuwa tashar wuya ta hanyar tsutsa mai tsutsa da infeed tauraro. A wurin canja wuri, ƙirar ciki, wanda ke sarrafa ta cam, axially yana motsawa cikin jikin gwangwani yayin juyawa, kuma ƙirar waje, wanda cam ɗin ke jagoranta, yana ciyarwa har sai ya dace da ƙirar ciki, yana kammala aikin wuyansa. Na'urar ta waje ta fara cirewa, kuma jikin na iya zama a kan ƙirar ciki don hana zamewa har sai ya isa wurin canja wuri, inda ya rabu da ƙirar ciki kuma an isar da shi zuwa tsarin flanging ta hanyar tauraro na waje. Yawanci, ana amfani da hanyoyi masu mahimmanci da kuma asymmetric necking: tsohon ana amfani da shi don 202-diamita iyawa, inda duka iyakar ke fama da wuyar ƙira don rage diamita zuwa 200. Ƙarshen na iya rage ƙarshen 202-diamita zuwa 200 da sauran ƙarshen zuwa 113, yayin da 211-diamita za a iya ragewa zuwa uku bayan 202, kuma za a iya rage darajar zuwa uku zuwa 200. ayyukan wuya.

Akwai manyan fasahohin wuya guda uku

- Mold wuyansa: Diamita na gwangwani na iya raguwa a ɗaya ko duka biyun a lokaci guda. Diamita a ƙarshen zobe na wuya ya yi daidai da ainihin diamita na iya jiki, kuma ɗayan ƙarshen yana daidai da madaidaicin diamita na wuyansa. Yayin aiki, zoben wuya yana motsawa tare da axis na jikin gwangwani, kuma ƙirar ciki tana hana wrinkling yayin tabbatar da daidaitaccen wuya. Kowace tasha tana da iyaka kan yadda za a iya rage diamita, dangane da ingancin kayan, kauri, da diamita. Kowane raguwa na iya rage diamita ta kusan 3mm, kuma tsarin wuyan tashoshi da yawa na iya rage shi da 8mm. Ba kamar gwangwani guda biyu ba, gwangwani guda uku ba su dace da maimaita wuyan ƙirƙira ba saboda rashin daidaituwar kayan abu a kabu na weld.

- Pin-bin wuya: Wannan fasaha ta samo asali ne daga ka'idoji guda biyu na iya wuya. Yana ba da damar ƙwanƙwasa santsi na geometric kuma yana iya ɗaukar wuyan matakai masu yawa. Adadin wuyansa zai iya kaiwa 13mm, dangane da kayan da iya diamita. Tsarin yana faruwa tsakanin ƙirar ciki mai jujjuyawa da ƙirar ƙirar waje, tare da adadin juyawa dangane da adadin wuya. Matsakaicin madaidaicin madaidaicin yana tabbatar da daidaituwa da watsa ƙarfin radial, yana hana nakasawa. Wannan tsari yana haifar da kyawawan lanƙwasa na geometric tare da ƙarancin asarar kayan abu.

- Mold kafa: Ya bambanta da ƙirar ƙira, jikin gwangwani yana faɗaɗa zuwa diamita da ake so, kuma ƙirar ƙira ta shiga daga ƙarshen duka biyun, yana daidaita madaidaicin wuyansa na ƙarshe. Wannan mataki-mataki-mataki na iya cimma santsi mai laushi, tare da ingancin kayan abu da amincin weld ɗin da ke ƙayyade bambancin wuya, wanda zai iya kaiwa har zuwa 10mm. Kyakkyawan tsari yana rage kaurin tinplate da 5%, amma yana riƙe kauri a wuyansa yayin haɓaka ƙarfin gabaɗaya.

Waɗannan fasahohin necking guda uku kowanne yana ba da fa'idodi dangane da takamaiman buƙatun tsarin masana'anta.

Bidiyon da ke da alaƙa na Tin Can Weld Machine

Chengdu Changtai Intelligent Equipment Co., Ltd.- Mai sarrafa kayan aiki ta atomatik mai kera da mai fitarwa, yana ba da duk hanyoyin magance Tin. Don sanin sabbin labarai na masana'antar shirya kayan ƙarfe, Nemo sabon tin na iya yin layin samarwa, da samun farashi game da Injin Don Za a iya Yi, Zaɓi Ingantacciyar Can Yin Injin A Changtai.

Tuntube muDon cikakkun bayanai game da injin:

Tel:+86 138 0801 1206

Whatsapp:+86 138 0801 1206 +86 134 0853 6218

Email:neo@ctcanmachine.com CEO@ctcanmachine.com

Lokacin aikawa: Oktoba-17-2024